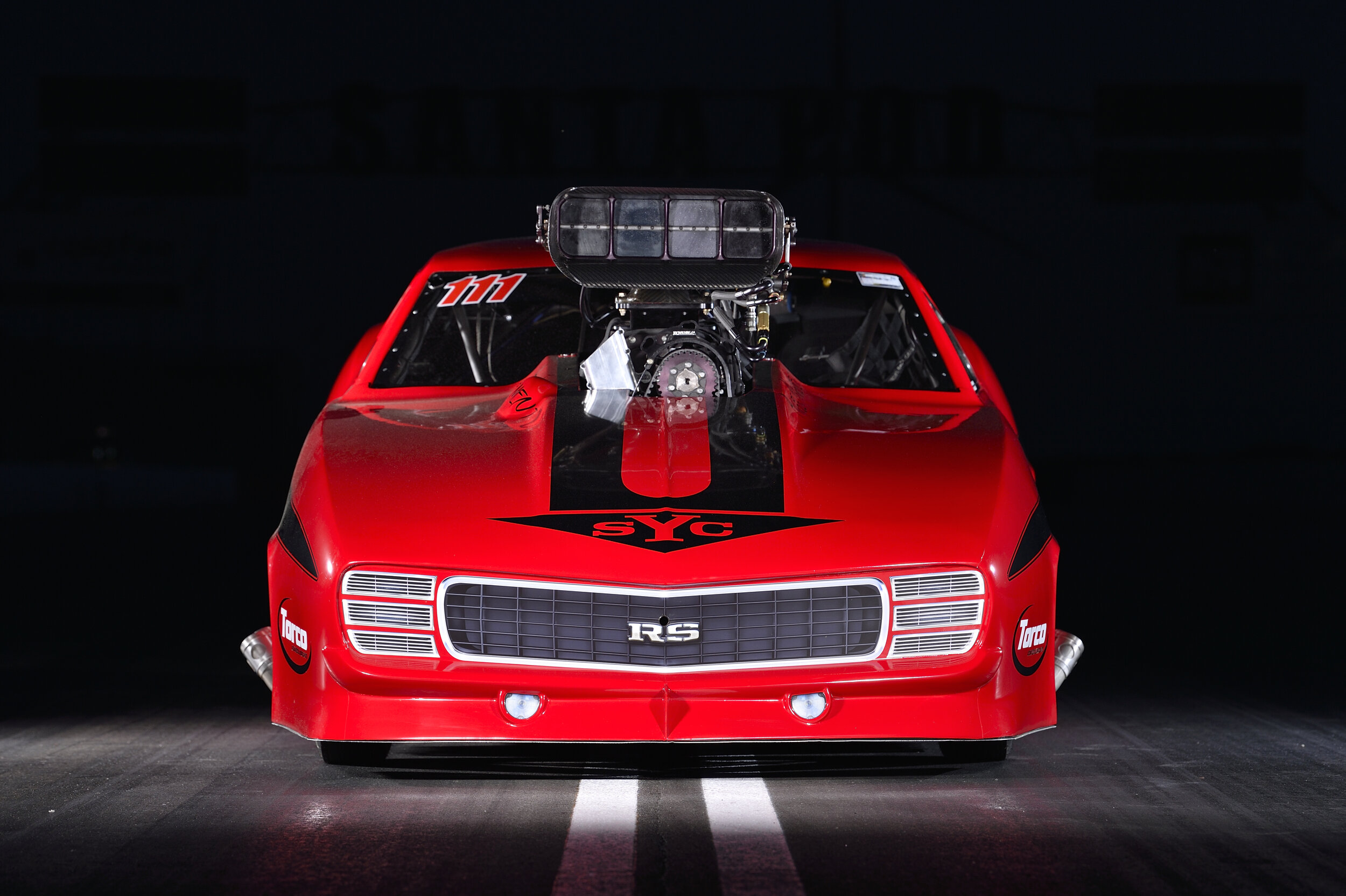

For all your race car engineering needs

RRC offers every kind of engineering and fabrication service necessary to build a complete race car.

We design and build:

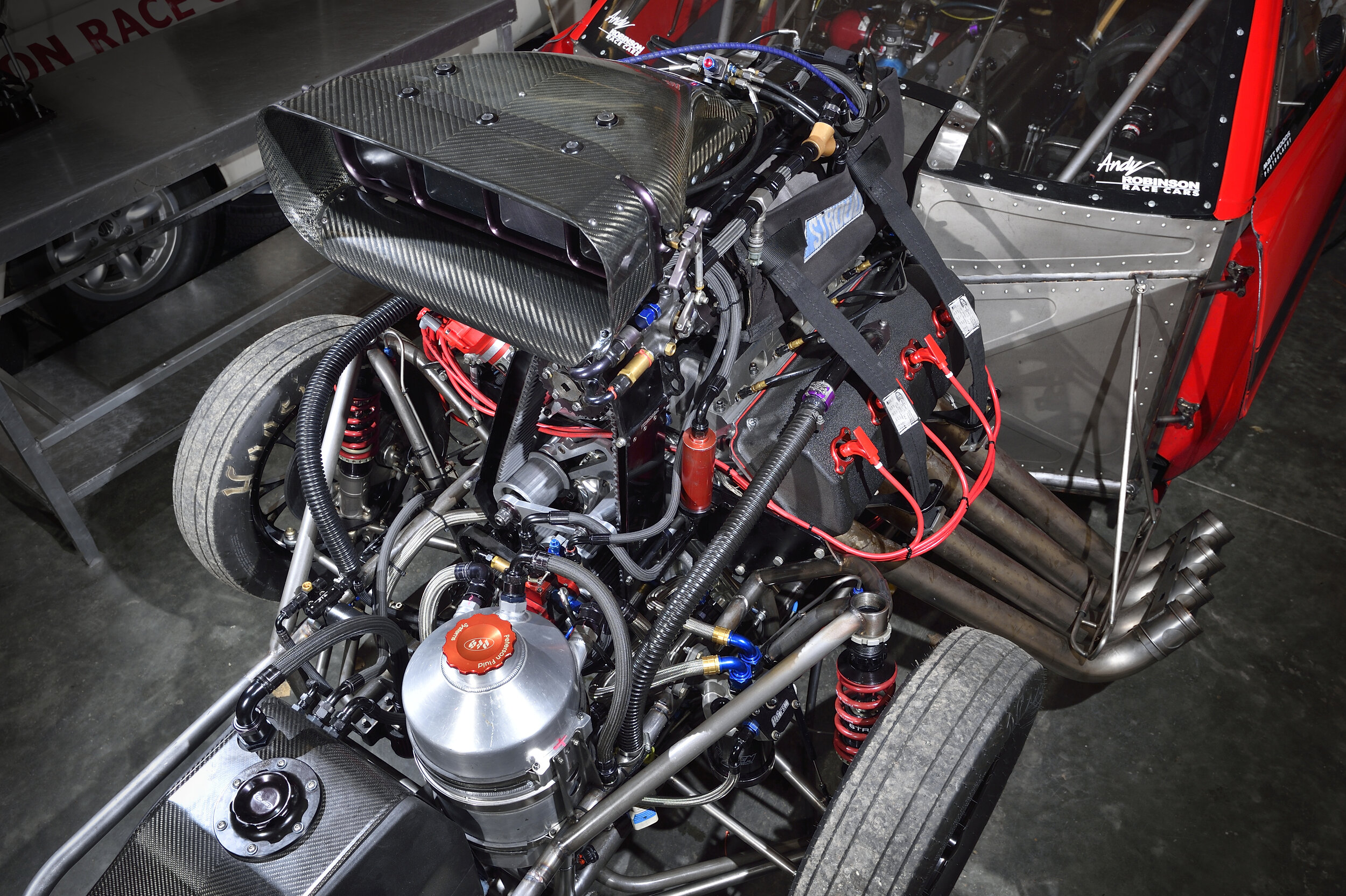

Spaceframe chassis

Bespoke Roll cages

Suspension systems (including 4 links)

Axles

Interior tinwork/composite panels

Inlet/Exhaust pipework

Aerodynamic aids

We can also supply:

Motorsport Plumbing

Wheels/Tyres

Axle Parts

Transmission/Torque Convertors/Clutches

Rod Ends

High Quality Hardware (AN/NAS)

Brakes

Safety Equipment